Our Company's Mission

East Iowa Plastics is dedicated to providing high quality, individualized service for our customers.

We are committed to continuous improvement in everything we do to achieve our goal of providing the best overall value to each customer. By doing so, we will build mutually beneficial, long lasting relationships with our customers, suppliers, and employees.

Our Company's History

East Iowa Plastics, Inc. was incorporated November 1, 1997, and is owned by Bret and Jean Kivell of Aurora, Iowa.

East Iowa Plastics has evolved over thirty years. Our company became the outstanding thermoforming facility it is today as a direct result of the experience, technology, and innovative product lines incorporated by the company's predecessors. Our history is a reflection of the recent advancements and growth in the thermoformed plastics industry.

East Iowa Plastics Today

The success of East Iowa Plastics today is measured by its sustained expansion. We continue to grow our customer base for custom thermoforming and we are constantly researching new and better production techniques and materials. Equipment modernization and investments in new equipment and highly qualified staff allow us to efficiently deliver the products needed to serve our customers. "If you need it, we can make it!"

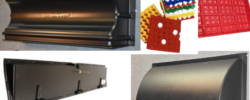

The past few years has also seen the expansion of our own product lines. New proprietary products include decorative top caps for our WeatherBest shutter line, innovative Pakster™ ventilation inlets for poultry houses, the best plastic egg flats in the industry, sun deflectors and light shields to help farmers become more efficient and a new style of feed tray. The housing and livestock industries we serve recognize East Iowa Plastics as an innovative manufacturer who can turn ideas into reality. We can help turn your ideas into reality.

East Iowa Plastics is successful because we recognize the importance of cost effectively providing our customers with superior products and service. Today and tomorrow, we are here to help our customers also be successful.

EAST IOWA PLASTICS HISTORY

East Iowa Plastics has been in business for 23 years and has been rated an A+ Accredited Business by the BBB since 2008!